The challenges of industrial roofs:

Reliable waterproofing on different material substrates and integration of complicated details.

The Triflex claim:

Solutions for permanently secure roof waterproofing with extended refurbishment intervals. Solutions for long-term profitability and minimised follow-up costs. Solutions for simple, detailed and complicated roof constructions with good connection possibilities. Solved together.

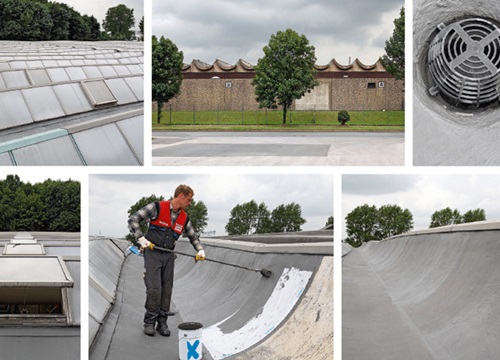

PU-insulated sawtooth roof

- Project: Industrial hall with sawtooth roof, Essen

- Solution: Triflex ProDetail

- Client: Sparkasse Essen

- Application: Homeier Bedachungen GmbH, Essen

- Area: 4,300 m²

- Substrate: In-situ PU foam

- Completion: 2008

Metal roof with rainwater gutter

- Project: Logistics hall, Teresin (Poland)

- Solution: Triflex ProDetail

- Client: Pro Logis

- Application: PHU Dekpo

- Area: 526 m rainwater gutter including 1,780 standing seams

- Substrate: Metal roof with bitumen sheeting

- Completion: 2010

Arched roof with hollow tile ceiling construction

- Project: Vattenfall Machine Hall, Berlin-Charlottenburg

- Solution: Triflex ProTect (area), ProDetail (joints)

- Client: Vattenfall Europe Berlin AG & Co. KG

- Application: Palluth Dachbau GmbH, Berlin

- Area: 3,300 m² and 1,500 running metres of junctions

- Substrate: Bituminous

- Completion: 2007

Special waterproofing of a metal roof

- Project: Tag Aviation, Cointrin Airport Geneva

- Solution: Triflex ProDetail, Triflex ProFibre

- Client: Tag Aviation Geneva

- Application: Piovano Etanchéité Yverdon

- Area: Connections and transitions on a roof over 10,000 m² in size

- Substrate: Metal

- Completion: 2009

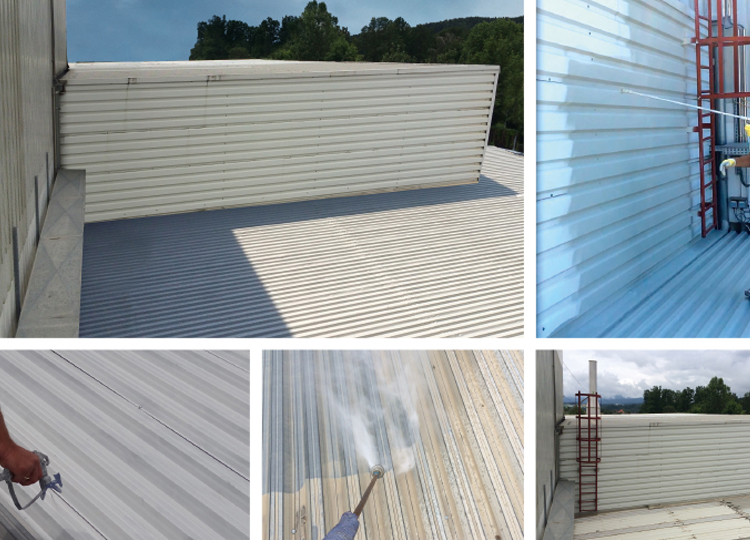

Metal roof with various details

- Project: TAIG Industrial Hall, Althofen, Austria

- Solution: Triflex Metal Coat/Triflex ProDetail

- Client: Treibacher Industrie AG

- Application: PCB Beschichtungstechnik, St. Veit an der Glan

- Surfaces/joints 1,300 m²/1,100 running metres

- Substrate: Trapezoidal sheet metal

- Completion: 2014