Applying PMMA-based liquid applied waterproofing used to be a purely manual job. Triflex SAM (Spray Application Machine) for mechanical application of two-component liquid applied waterproofing is a real innovation in the construction industry. The use of machine technology allows contractors to plan the worksite in a completely new way. Large roofs and multi-storey car parks can be coated faster and with consistent quality - and with a smaller workforce.

Based on more than 45 years of experience and development work in the field of liquid applied waterproofing, Triflex SAM represents a symbiosis of manual working and machine application for details and surfaces.

Who is Triflex SAM?

Want to see how it works?

If you want to see how Triflex SAM works, book a local demonstration. Just fill the fields below and send your request. We will be happy to meet you face-to-face and introduce our innovation in mechanical application of two-component liquid applied waterproofing.

Reliable waterproofing and coating of roofs with Triflex SAM

- Short installation times and fast refurbishments

- Smaller workforce required for worksites

- Consistent application quality for priming, waterproofing and finishing

- Containerised material prevents wastage

- Regulation-compliant waterproofing guaranteed thanks to machine application

- Ergonomic standing position for operators

- Triflex SAM is craneable

Short closure times in multi-storey car parks with Triflex SAM

- Suitable for large areas, such as parking decks, straight and spiral ramps, underground car parks and access routes

- Short installation times and shorter closures

- Refurbishment without removing the old covering

- Smaller workforce for refurbishing multi-storey car parks

- Consistent application quality for priming, waterproofing and finishing

- Containerised material prevents wastage

The new spray alternative to polyurethane and polyurea

- Volume-controlled spay mechanism for a precise application.

- Chemical bonding between PMMA primers, waterproofing and finish coatings.

- Minimum of overspray to protect the environment.

- Free of Isocyanates

- Rainproof after just 30 minutes and completely cured after 45 minutes for a fast project implementation

- Application temperatures down to 0°C for a reliable planning and application regardless of the weather conditions and time of year.

- Resistant to alkali, hydrolysis and UV light

Your contact

If you are interested in Triflex SAM and would like to hire the machine for your construction project with your crew, simply contact the Triflex International Sales Manager Janik Schuette. He will be happy to help you with any technical questions relating to your project and the use of Triflex SAM.

Janik Schuette

International Sales Manager Triflex

+49 160 92548051

janik.schuette@triflex.de

Triflex SAM in practice

What challenges has Triflex SAM already solved? Where have SAM and his crew been deployed? Over the coming months, we will be regularly uploading new reference projects from the field of roof and multi-storey car park refurbishment to show you the innovative spray application method for two-component liquid applied waterproofing in actual use.

Fast and uncomplicated multi-storey car park refurbishment with Triflex SAM

The surface of the multi-storey car park had suffered moisture damage and was in urgent need of refurbishment. The challenge: fast, safe and reliable application of waterproofing while the car park was still in operation. Once all the detail waterproofing and priming work was completed, Triflex SAM was used to coat an area of around 3,000 m². Triflex SAM and his crew from K-T-K GmbH in Warstein were able to waterproof the area with a team of four in just 2.5 working days. You will find all the information and project data in our reference project.

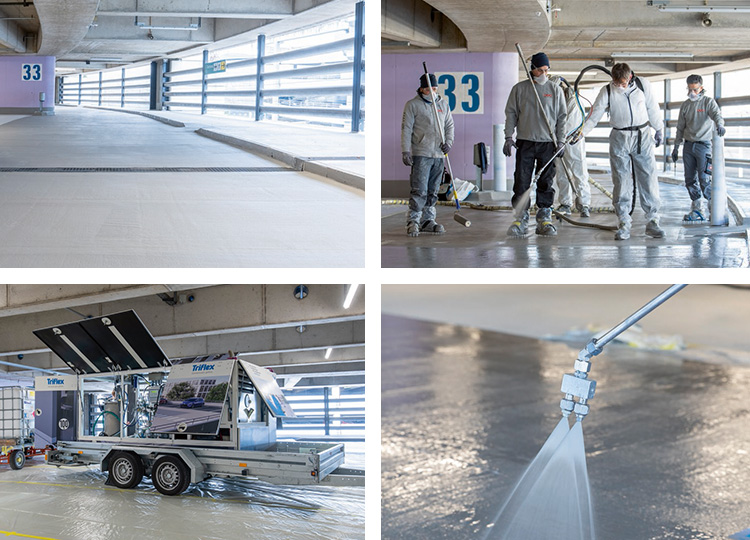

Simple refurbishment of multi-storey car park at Düsseldorf Airport using Triflex SAM

After intensive use of the multi-storey car park, and some partial repairs, Düsseldorf Airport decided on a more permanent solution. A total area of 22,000 m² was refurbished on level 33 of multi-storey car park P3 at Düsseldorf Airport. Together, Triflex SAM and his crew from K-T-K GmbH in Warstein successfully tackled the diverse demands of the park deck and the challenge of carrying out refurbishment in stages. A surface area of 6,000 m² was refurbished with Triflex SAM in the space of 5 working days. You will find all the information and project data in our reference project.